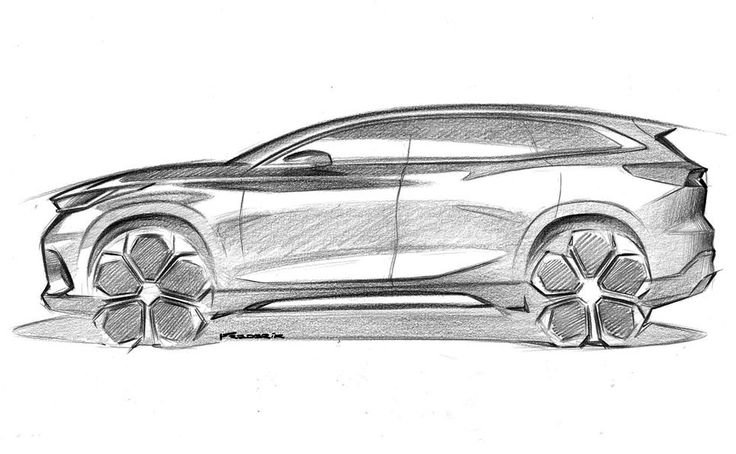

The Complex Web of Considerations in Car Design

Crafting a car isn’t simply welding metal sheets and stuffing in an engine. It’s a meticulous dance between artistic vision, technical prowess, and market demands, where every detail, from the curve of the hood to the softness of the seat, is a deliberate decision. Let’s delve into the multifaceted world of car design, exploring the key considerations that manufacturers juggle to bring their four-wheeled creations to life.

1. Target Audience and Market Trends:

Understanding who will drive the car is paramount. A family SUV needs spacious interiors and safety features, while a sporty coupe targets thrill-seekers with sleek profiles and powerful engines. Market research dictates design trends, with manufacturers analyzing demographics, income levels, and driving habits to tailor their offerings. For example, the rise of eco-conscious consumers led to a surge in hybrid and electric vehicle development.

Example: Ford Mustang’s aggressive design and powerful engine cater to driving enthusiasts seeking performance and excitement, while the Honda Odyssey minivan boasts a spacious interior and child-friendly features, perfectly aligned with family needs.

2. Safety and Regulations:

Safety isn’t an option, it’s an obligation. Crash test ratings, emissions standards, and pedestrian protection regulations are all critical factors influencing design. Advanced materials like high-strength steel and improved crumple zones enhance safety, while features like airbags and autonomous emergency braking become increasingly sophisticated.

Example: Volvo is renowned for its focus on safety, incorporating features like whiplash protection seats and pedestrian detection systems into their designs. Stringent European emission standards have spurred the development of fuel-efficient engines and hybrid technologies across various carmakers.

3. Performance and Efficiency:

The perfect balance between power and fuel economy is a constant pursuit. Aerodynamics play a crucial role, with sculpted body lines and lightweight materials reducing drag. Engine development focuses on maximizing power output while minimizing fuel consumption. Transmission technologies like CVTs and hybrid systems improve efficiency further.

Example: Tesla’s sleek electric vehicles prioritize aerodynamic design for maximum range, while BMW’s EfficientDynamics technologies help their cars achieve impressive fuel economy without sacrificing performance.

4. Cost and Production Feasibility:

A dream car on paper might be a cost nightmare in production. Manufacturers carefully select materials and design elements that are budget-friendly and can be efficiently mass-produced. Advanced manufacturing techniques like robotics and 3D printing enable complex designs while maintaining profitability.

Example: Toyota’s Prius, despite its innovative hybrid technology, was designed with cost-effective materials and streamlined assembly processes, keeping it accessible to a broader market.

5. Brand Identity and Emotional Appeal:

Cars are more than just machines; they’re symbols of personality and aspiration. Design teams strive to imbue their creations with a unique identity that resonates with their target audience. Bold grilles, distinctive headlights, and signature paint colors are all tools to convey a brand’s message and evoke emotions.

Example: The iconic curves of the Porsche 911 instantly signal luxury and performance, while the rugged and utilitarian design of a Jeep Wrangler speaks to adventure and off-road prowess.

The Takeaway:

Designing a car is a complex tapestry woven from market research, safety regulations, technological advancements, cost constraints, and emotional appeal. Each detail, from the material of the seatbelt to the curve of the fender, is a calculated decision carefully considered by manufacturers. Understanding these considerations gives us a deeper appreciation for the remarkable journey a car takes from concept sketch to showroom floor, where it ultimately meets its destiny on the open road.

Add a comment Cancel reply

Categories

- Car Gadgets (17)

- Car News (33)

- Car Reviews (43)

- Car Wars (7)

- Mechanicals (32)

- Uncategorized (2)

Recent Posts

About us

Popular Tags

Related posts

The New Car Smell: What you need to Know

The Drawbacks of Stretched Sedans: Cruising in Comfort or Compromising Convenience?